During the path of our research on storage systems, we came across several terms we did not understand. We thought that there may be other students facing the same problem too, so we decided to include a glossary in addition to our common research. We sincerely hope to have improved your understanding of storage systems through our blog. Thank you for browsing & feel free to comment / tag. Cheers! =D

From the creators:

Honeycombing (pg 125) :

The internal fiber separation of drying timber. The roughness & weakening on the face of a concrete wall due to segregation of the concrete, with the result that there is little sand to fill in between the stone aggregate.

Cantilever (pg 127):

A projecting structure, such as a beam, that is supported at one end and carries a load at the other end or along its length.

Turret trucks (pg 131):

Very narrow aisle (VNA) equipment.

Gravity conveyors (pg 133):

Any un-powered conveyor, such as a gravity chute or a roller conveyor, which uses the force of gravity to move materials over a downward path.

Sprocket (pg 133):

Gear or wheel with metal teethes that meshes with a chain or track.

Spigots (pg 133):

Small wooden plug, faucet or Tap (valve).

Baulks (pg 134):

Something immaterial that interferes with or delays action or progress.

Gangway (pg 134):

A temporary passageway of planks.

Linoleum (pg 134):

A floor covering made from solidified linseed oil (linoxyn) in combination with wood flour or cork dust over a burlap or canvas backing.

Quick-Crate

Containers made entirely from plywood, Quick-Crate boxes, allows full product access from top or any side and can be collapsed to 9 in. high when not in use. Loaded crates can be stacked to maximize storage capacity. Exempt from ISPM-15 import/export regulations, products are certified by US Army's Defense Ammunition Center for transportation of live ammunition. Other uses include automotive and aerospace applications where products must be loaded or unloaded on assembly line.

Quick-Crate is a cost-effective, collapsible, reusable shipping crate system designed to replace traditional one-way boxes. Each Quick-Crate box is designed around application specific criteria (internal dimensions, load distribution and product support).

Shipping Container Features Slot and Tab Design

The new Slot Lock Container (SLC) is extremely easy and quick to assemble. No nails, screws, or staples are required for assembly. The SLC has no loose fasteners and is light weight when compared to other wooden boxes and crates. The SLC can also be reused many times if desired or used as a one way shipper.

SLC are made from 7/16" on grade OSB sheet material and are supplied with a heavy duty pallet base. The unique slot and tab design provides a durable shipping container. Individuals may load from the side with only two or three panels secured. No more lifting over the sides to load pallet boxes or crates. Simply apply steel or plastic/nylon banding around the container when loaded and this will lock the panels together as one container.

The traditional design of parallel aisles:

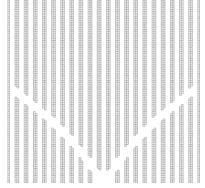

24 Jan. 2007, in a web cast sponsored by Warehousing Education and Research Council, a pair of professors will discuss 2 new approaches to aisle layout: the Gull Wing Aisle & the Fishbone Aisle & why they believe the layouts could decrease distances travelled by as much as 20%.

(a) Gull Wing Aisle

2 diagonal cross aisles originate from the same pickup-and-deposit point to make a ‘v' in roughly half of the total space, giving workers a straight-line advantage when traveling to and from some of the pick locations.

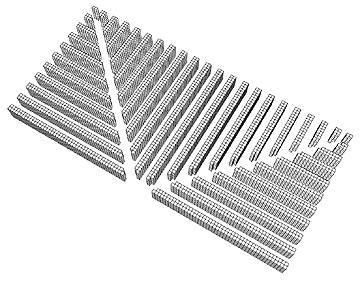

(b) Fishbone Aisle

This v-shaped cross aisle allows order pickers to travel to order picking storage areas as quickly as possible with its branch-like features.

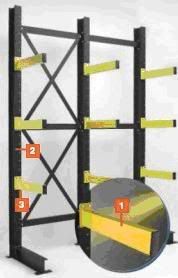

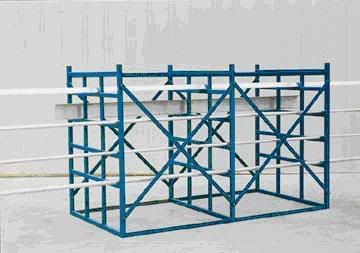

Cantilever Racking Systems

Cantilever Racking Systems are designed for the safe and efficient storage of longer or bulkier products. It maximises storage space with easy accessibility and excellent product presentation. Cantilever Racking is an adaptable and flexible system that allows for safe, convenient storage for a variety of products. It has no front columns to interfere with the placement or retrieval of loads.

Functions of Cantilever Racking Systems

- Safe and neat storage of long products

- Maximises usage of floor space

- Each rack designed and manufactured to suit individual requirements

- Robust design to cope with arduous environments

- Ideal for plywood & timber, building materials, pipe & tubing, sheet steel, goods, extrusions

Features & Specifications of Cantilever Racking Systems

- Arms positively secured in position using two high tensile, zinc plated bolts

- Arms adjustable on a typical pitch of 150 mm, which can be varied if required

- All upright and base sections are manufactured from hot rolled universal beam sections

- Arms manufactured from universal beam or rectangular hollow sections

- The latest computer technology is used to achieve the most efficient design

- Minimum safety factor of 2.8 based on ultimate tensile strength

- Arm deflection limited to 1/150 of length

- Upright deflection limited to lesser of 1/120 of height or 50 mm

- Maximum allowable weld stress of 115 N/mm 2

A cantilever is a beam that is supported at one end and carries a load at the other end or along its length, having the other end suspended in the air. The beam forms a lever, which carries the load by being held in position by the mount, turning the loads into torque on the mount.

Cantilever construction allows for long structures without external bracing which comprises of:

1-Cantilevered beam

2-Supporting post

3-Location of torque

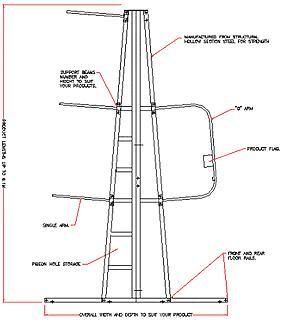

Vertical Racking System

Vertical racking is designed for vertical storage of tubing, pipe and other types of similar materials. It enables the organization of pipes, extrusions etc. in a systematic and readily accessible manner. Vertical racking utilises the minimum amount of space for storage of products.

Features & Specifications of Vertical Racking System

- Sturdy construction which supports the items

- Arms adjustable horizontally without use of tools

- Standard location depth 600 mm but any depth available

- Bay centres designed to suit space available

- Heights from 2 metres to 6 metres

- Single- or double-sided

- Floor retaining angle keeps stock safely in rack

Palletstor Racking System

The Palletstor racking system is the solution to all heavy-duty storage applications.It is one of the most widely used pallet racking systems available today which has evolved through in-depth knowledge of storage and handling techniques gained during many years experience in the industry.

Features & Specifications of Palletstor Racking System

Adjustable But Strong & Rigid

Beams can be removed and repositioned when changes in the use of the racking occur. Although Palletstor is adjustable, once the beams are slotted into position in the frame uprights, an inter-locking structure of great strength and rigidity is maintained. Each beam is supplied complete with a pair of steel Safety Locking Pins. When located they ensure the beam is correctly positioned and help prevent the beam being dislodged during use.

Palletstor racking beam with safety locking pin

Palletstor racking beam with safety locking pin

Safety locking pin

Safety locking pin

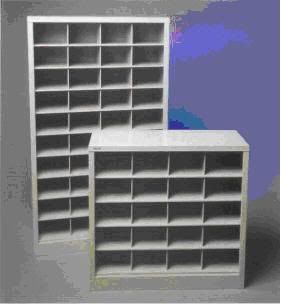

Pigeon-Hole Racking

Pigeon-Hole Racking is suitable for a wide range of products and applications. It allows easy identification and retrieval of materials and suitable for automobile parts, hardwareitems and for many other products.

Heavy Duty Systems

It is also known as Pallets Racking system. This storage system is designed to take maximum load upto 2 tons per load.

Applications

This design is suitable for Raw-material and finished product storage for each & every industry.

(A) DYNAMIC SYSTEMS

Effectively utilising floor and cubic space, dynamic push back racking is amongst the most space efficient pallet racking storage systems available. Push Back uses gravity fed telescoping carts to provide high density dynamic storage. Pallets are loaded in sequence onto wheeled carriers of differing heights and are pushed back along inclined steel guide channels to utilise the full depth of the pallet racking. Pallets can be stored upto four deep and when a load is retrieved the remaining pallets roll forward into position at the picking face.

Pallets retrieved on a ‘first-in, last-out' basis and with each product having a dedicated lane. Dynamic push back racking is particularly useful in marshaling areas, and for long term storage and handling.

Benefits:

- Exceptional space utilization

- Good aisle selectivity

- More picking faces/ fewer aisles

*Available in Roll Form or Structural Materials

Push back racking

A dynamic storage system where pallets are stored two, three or four deep. Pallets are placed onto the front position and subsequent pallets are then added by 'pushing back' the front pallet. Retrieval is the reverse of this procedure with pallets returning under gravity. This system can be accessed using most standard types of fork-truck.

Carton Flow Racking

Carton live storage or ‘flow racking' operates on the same principle as pallet live storage, but is used for stock which needs to be hand-loaded and picked. Live storage systems reduce order picking times and help minimise errors, as not only are items presented precisely at the picking face, but effective management of the throughput and stock levels of goods can also be easily maintained.

(B) MECHANISED SYSTEMS

Carousel systems are automated storage and retrieval systems (ASRS) which are made of shelves / bins and chains and are operated electrically to store and retrieve stocks to workers' locations as required (parts-to-picker).

Advantages of Carousel Systems:

- Minimise operator dependency & movement

- Improve inventory accessibility & security

- Improve order picking efficiency & productivity

- Time & cost savings

- Cubic utilisation

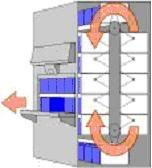

2 Types of Carousel Systems:

1) Vertical Carousel System

- Similar to High Bay but without loss of storage space

- Compact shelves geared to size & weight of articles stored

- Height Optimisation

- High flexibility

2) Horizontal Carousal System

- Series of storage bins suspended from a horizontal, continuous overhead chain

- Bins rotate in a closed-looped oval track

- Requested items routed to operator or picker

- E.g. Hospitals

A) LIVE STORAGE

Pallet Live Racking

Working on a ‘first-in, first-out' basis, dynamic live pallet racking provides extremely high levels of storage density in a given area. Pallets are loaded onto dedicated lanes of inclined gravity feed rollers which are set at a fixed gradient. When a load is taken from the picking face, the next pallet rolls into position, with replenishment stock loaded at the opposite (upper) end of the lane. Stock rotation is therefore automatic with the minimum of fork lift truck movements required to handle the flow of goods.

Fast Pallet Access

Pallet loads can be entered and removed from single dedicated lanes. Gravity tracks are set at a fixed gradient allowing pallet loads to roll from the input face by gravity to the output face, eliminating fork lift truck movement.

System Flexibility

The dynamics can be specified to suit a wide load range. Speed controllers provide regulated movement of pallet loads to the pick face. Rollers, uprights and beams can be made to any length to suit the pallet/product size. The fitting of a pallet separator at the output position of each lane will allow zero line pressure.

‘First in'-‘First out'

Speed of throughput combined with automatic stock rotation is the major advantage of this system.

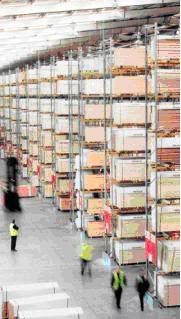

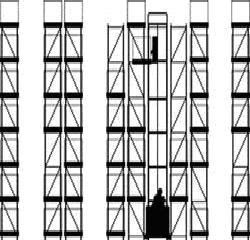

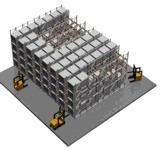

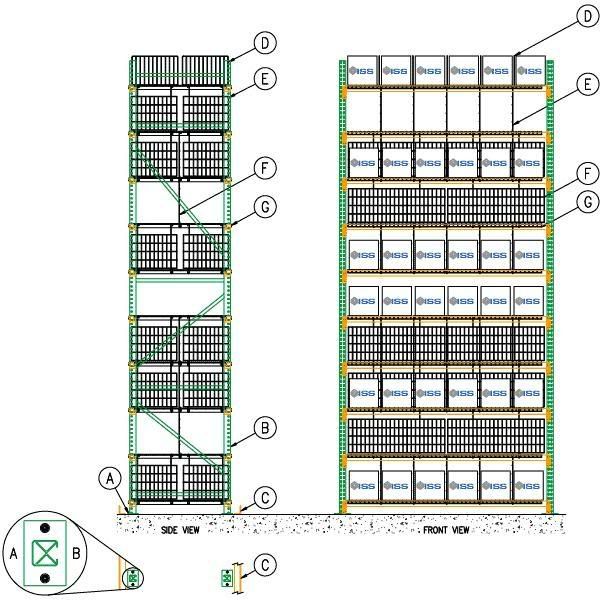

B) HIGH RACK NARROW AISLE RACKING

- Narrow Aisle Rack is a high density type of Carton Storage System that offers immediate access to every carton stored in very narrow aisles.

- Narrow aisle racking is served by specially designed trucks or stacker cranes.

- Narrow aisle free path stackers are equipped with rotating or sliding pallet handling mechanism on the mast, which do not have to turn through 90 degrees in the aisle to pick up or set down a pallet load.

- The gangways are only marginally wider than handling equipments.

- If trucks are used, the guide rails or electrical wire guidance will be used to constrain and guide the trucks along the gangways and not to turn to retrieve or deposit a pallet. The mask or fork head rotates to left or right as required.

- Narrow aisle truck can operate to greater heights than conventional trucks - up to 14 m.

- Specialised forklifts called Turret (turret trucks are expensive) or SwingReach trucks and Automatic Stacker Cranes (AS/RS) that operate in aisles not much wider than the load itself, can increase the use of available space. Head space too is effectively used in high-rise narrow aisle applications. Although capital cost typically increases, there are usually savings in land and building costs.

- Narrow aisle racking consists of the same basic components as conventional racking but with runs placed closer together eliminating the wasted space of a wide aisle. The pallets can be stored to a greater height to maximise all available cubic space. The pallets are accessed via specialist trucks, which are guided in the very narrow aisles by either low or high profile floor mounted rails or electronic wire guidance in the floor.

- The principal advantages of narrow aisle racking includes:

- The combination of relatively high density with 100% individual selectivity

- Throughput speed can be more rapid than with conventional trucks and layouts

- 100% accessibility to individual pallets

- Configuration for maximum storage, density and efficiency

- Specialist narrow aisle fork-lift trucks are required to work in the reduced aisle

- Better space utilisation

- Good occupancy rates

3-D Diagram

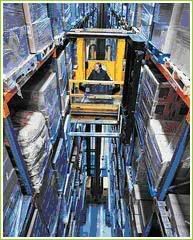

C) HIGH BAY

- The automatic storage of pallets in high bays is an efficient way of storing a large number of different articles. All in and outfeed via stacker cranes and conveying systems in front of the high bay are carried out automatically.

- Controlled by Windows-based software.

- High bay pallet racking can reach up to a height of 30M to 35M.

- Racking for fully automatic installations.

- High-bay solutions reduce the cost of space needed for storage while offering all of the benefits of automation. Working either with pallet or other unit loads or mini-loads, including cases and totes.

- High-bay storage solution enables higher throughputs and space utilization, as well as increased order accuracy and inventory control.

- Fully automated high-bay AS/RS solutions allow 24/7/365 operation that provides labor savings, improved productivity and substantially reduced downtime.